The author used two of these in conjunction with a Comberton 12-2 mixer, an AH balanced line 8-4 stage mixer (very similar cabinet design) with a variety of tape decks (Akai 4000, Sony TC-377/399/630, Tandberg 3400X, TEAC 3340, Revox A77, Akai GXC 46D, Beocord 5000, etc) and speakers (KEF, BW, custom). A Saturn transcriptor with a SME 3012 would have suited this amp.

The P60 was the culmination of the many lessons learned on the P50 and still available until the early '80s at a cost of about £289 with the matching T55 tuner at £169, both being rather expensive for the time. These designs have proved to be quite reliable compared to earlier attempts, the (retrograde?) use of the DIN input convention and the loud switch-on transient through the speakers being the predominant short-comings. The latter could be overcome by using a soft-start which could be fitted inside the unit.

An unconventional but high quality build, some considered the placement of volume, balance and mono controls before the tape outputs as inconvenient. However, the facility for up to three tape decks to be used, the tape 2 output following the lo-filter and tone controls, could be useful.

This protection only turns on at the equivalent of 50W into a 2 ohm load and when it does it only adds a moderate distortion (0.2% typically) as distinct from clipping (V limit = 75V, I limit = 5A). The small capacitor prevents protection 'spikes' from appearing on the output and a LED drive circuit is triggered. Rated, by the author, to be one of the most succinct and successful systems seen.

Neil Williams has kindly shared the experience of restoring a P60 which I've taken the liberty of adding below.

"Paul,

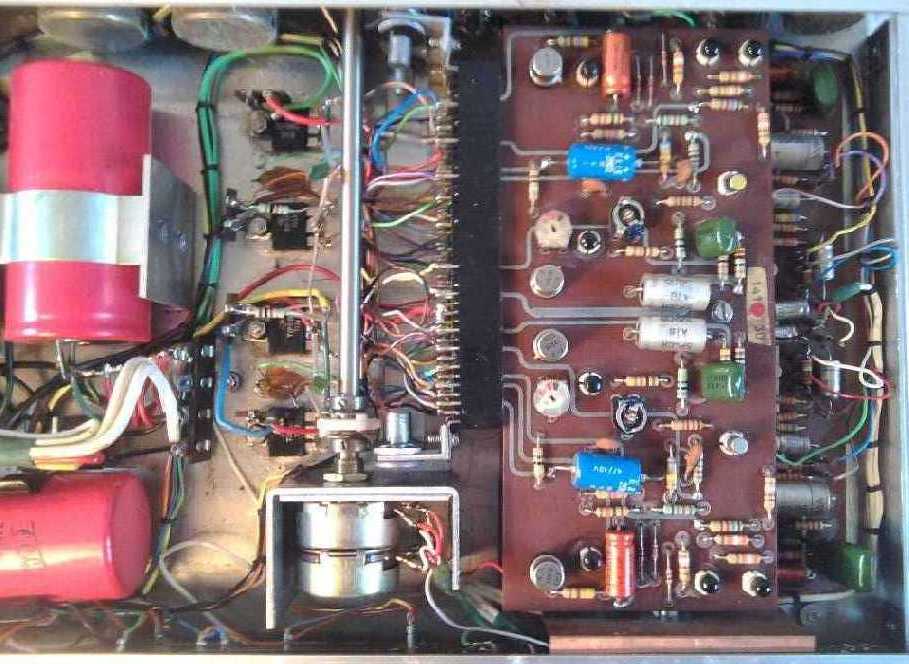

Well, here goes. I've attached some photos of my P60. It's pretty obvious what they all

are so I won't add any explanations.

As to "how I fixed my P60" here are the details.

After using the pre-amp section to copy some vinyl records to CD, I noticed that the

volume was way down one one channel. Using the various inputs and outputs to feed

signals from a CD player into the amplifier I determined that:

1. Both power amps appeared fine

2. Channel A was quieter than channel B between the tape 1 input and the tape 2

output. This means a problem in channel A in the tone control section.

3. Channel B was quieter between the cassette input and the tape 1 output.

This means a problem in the volume, balance or equalization stages.

I only had a clunky old AVO meter which has minimum ranges of 2.5V AC and DC so

it's hard to trace audio signals. I was able to compare DC voltages on all the transistors

between the two channels and they were basically the same. I also checked the impedance

of all the transistor connections as described in page 15 of the service manual and found

nothing abnormal there.

Without an oscilloscope, I had to come up with a way of tracing audio signals. The P60 is

a great tool for this as the tape 2 input splits the amplifier into two halves. I used a normal

phono lead plugged into the tape 2 input with a short length of wire taped to the centre of

one of the input plugs and a speaker plugged into the output of that channel. I didn't have

a signal generator either (I do now - I downloaded an app for my iPad which works fine)

so I used a CD player plugged into the cassette input. This method does affect the DC

levels in the amplifier as it places the volume control (47K) between the test point and

0V. Use of an electrolytic capacitor on the test lead stops this, but I didn't see any problems

without it.

By touching the lead on various points in the circuit and comparing the signal level between

channels, I was able to determine that C13 was bad on channel B.

The other fault was a little harder to track down. Following signals in the tone control section

(which necessitated removal of the front bezel to get at the potentiometer connections on

the circuit board) showed one channel consistently quieter than the other. I could not find a

fault in this channel and eventually realised that the fault was in the channel with the louder

signals! This brought me to the conclusion that it was probably C22 at fault since in normal

operation the path through Q6 would attenuate the signal in the tone control circuit. Checking

C22 showed that it was open circuit.

I replaced these two capacitors and the amplifier worked fine. I have since replaced all the

electrolytic capacitors in the pre-amp and LED operation circuits (I found that C36 was

faulty, too, as one of the leads was rotted away!).

I also replaced R101 in the power LED circuit as the original component was burned and

the LED only glowed very dimly. I looked for a 1W resistor but could not find one so I

used the 1/2W value that was originally there. This component in under rated and should

really be 1W.

I now have a digital voltmeter which would have helped the testing enormously along with

the iPad signal generator app.

Deciding to replace all the electrolytic capacitors as the first step would have been a good

move, too! Hindsight is always 20 - 20!

I hope this is useful. Feel free to edit the above as much as you want. The photos are now

yours to publish.

Best regards and thanks again for the very helpful P60 service manual.

By the way: there is a P60 circuit diagram floating around on the web which incorrectly

shows C44 across R1. It is really across R3 as your information and the service manual show.

Cheers,

Neil Williams."

No problem, Neil. Any time. An excellent demonstration of deductive logic with limited resource. It's often an idea to consider replacing all the electrolytics in the signal paths of an amplifier of this age since these are the likeliest components to fail first and it makes life easier doing this in one go rather than repeatedly disassembling the unit. Then specifying a high temperature, high frequency type will increase longevity and (theoretically) improve performance too. The original PSU electrolytics (4,700µF, 63V) can be replaced with superior values but a soft-start (as mentioned above) should be included. The heat generated across the tarnished contacts of the mains switch on one volume control caused it to incinerate quite spectacularly. Thought also could be given to replacing the quiescent current carbon skeleton pots with sealed, multi-turn cermet types.

The distinctive input selector knob was supplemented by the unique indicators on the preamp level. The colour scheme changed from polished aluminium and black lettering. In a later version (PCB iss 3) the polished finish was retained.

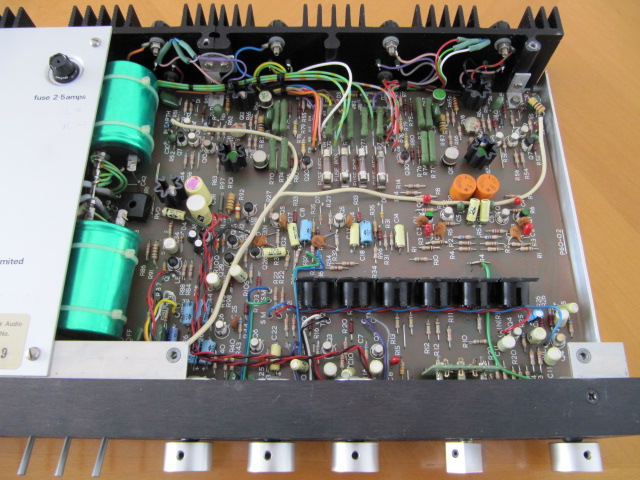

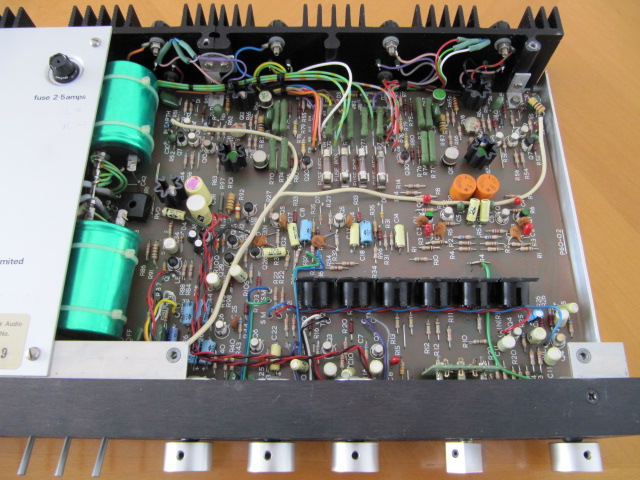

The PCB's 'upside-down' position was determined by there being no room on the rear panel for the input sockets this been taken up almost entirely by the heat-sinking for the output pairs (now very sensibly radiating outside the unit). It is arguable that internal air-flow around the components would be reduced, but this was essentially limited anyway.

Output stages using devices with a relatively low fT of 2MHz like these might cope with lengthy wiring runs (PA PCB track layout 90° wrt to heat-sinks) but, as in the System A, these arrangements can give rise to instabilities which could, or should, have been designed out. Note also how the PA input leads (white) snake around the board and are then held in place by unrelated components. The signal path should flow topographically from input to output.

This arrangement with the input sockets directly mounted on the PCB rather than the chassis, whilst reducing wiring, could prove problematic with the plastic sockets prone to breakage if care was not taken fitting connectors. From an aesthetic point of view these further disappointed since identical sockets could be found on far cheaper Thorn (eg; Bush, Ferguson, etc) products and, frankly for the price, one expected better. A similar arrangement was used in the complex Beomaster 6000 making access more awkward, the (hefty) unit then having to be lifted when change was required. I recall one unhappy customer whose precious wooden top had been deeply scratched by the metalwork when doing this.

The switch to DIN connectors discouraged a number of potential buyers like the author who, for good reason like previous Cambridge Audio designs, had already adopted the RCA phono convention and then Technics gear.

Notwithstanding this type's fall from 'serious' use, of domestic gear of this vintage I am torn between this amp and the Armstrong 600 series (PA) particularly because of the latter's tuner (623/6, designed by Ted Rule) for which I built a number of AM loop antennae specifically for Luxembourg (208m) and pirates. Note how the P110 also emulated the 600's styling "with a cut-away black base. The effect was to make the box seem thinner and smaller and seem as if it was floating above the table". In this model the P50 front panel layout was retained.

The later protection and muting circuit is shown below. Note the incorrect connections with regards mains E and the negative rail.

Contact me at paulkemble@hotmail.com

especially if you want additional content to this page

or if you find

any links that don't work. Don't forget

to add the page title or URL. Take care!

Back to index, sound, tips or home.